SOLUTIONS FOR TRANSPORTATION AND LOGISTICS

Transport & Logistics processes are inherent at many points in the supply chain and embedded in different sectors and companies. For an efficient supply chain, it is essential that all information is shared and integrated.

Differentiation in this sector is based on the quality and efficiency of operations.

Depending on the environment and the volume of goods movements, it defines the possibility of automating or not the execution of a specific process. In any case, logistics operations require a millimetric integration between all of them in order for the operation as a whole to be effective and efficient.

Operations can be carried out inside or outside the company’s physical facilities. However, this does not mean that these processes are external to the company. All processes must be centrally controlled and managed.

Optimization in execution and integration of all processes in the company’s corporate systems are fundamental to achieve these objectives. The implementation of technological solutions and the adoption of best practices will allow for greater efficiency and more accurate management.

The following are the most common processes, although it is important to note that each company may have additional processes that reflect its unique value proposition in the marketplace.

At Tech id we want to help you differentiate yourself by applying different technologies to the execution and management of your processes.

What processes can we help you with?

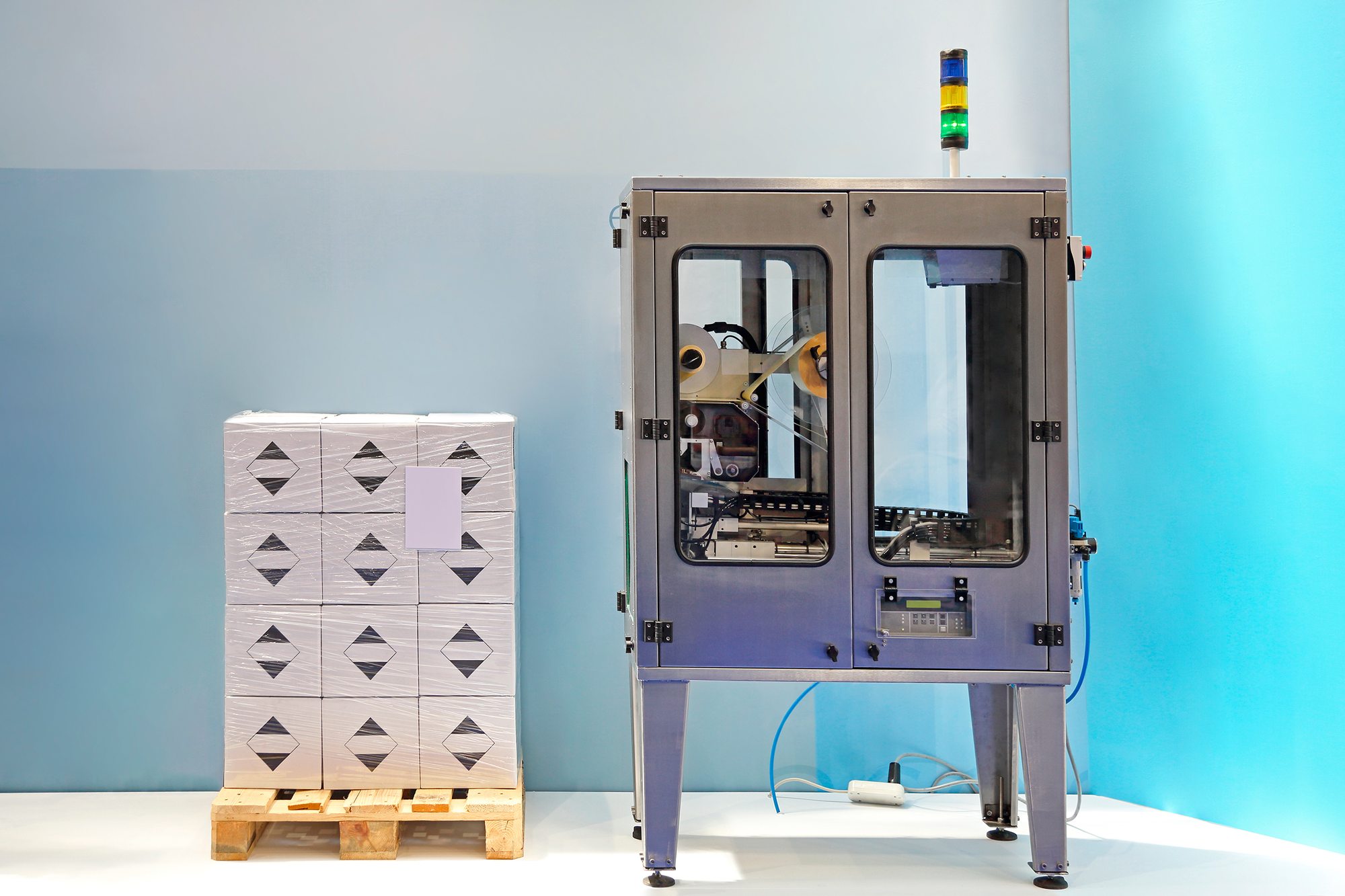

Identification and Labeling Systems

In order to optimize your processes, it is essential to physically identify the goods. The downstream processes and the logistics unit to be managed will define both the identification technology (barcodes, two-dimensional, RFID,…) and the identification process.

At Tech Id we help you to study the complete chain to determine the appropriate identification technology and how to execute the identification of your goods.

Identification and Labeling Systems

In order to optimize your processes, it is essential to physically identify the goods. The downstream processes and the logistics unit to be managed will define both the identification technology (barcodes, two-dimensional, RFID,…) and the identification process.

At Tech Id we help you to study the complete chain to determine the appropriate identification technology and how to execute the identification of your goods.

Inbound-Shipment Control and Internal Movements

The corporate systems (ERP, WMS, MES,…) are in charge of managing the stock and keeping it alive. Normally it will require complementary systems that help them to convert into data (digitize) the actual physical movements and therefore it becomes essential to have the integration of technology in their management and control systems.

Complex automation or simple controls are possible, but with a view to process efficiency.

Inbound-Shipment Control and Internal Movements

The corporate systems (ERP, WMS, MES,…) are in charge of managing the stock and keeping it alive. Normally it will require complementary systems that help them to convert into data (digitize) the actual physical movements and therefore it becomes essential to have the integration of technology in their management and control systems. Complex automation or simple controls are possible, but with a view to process efficiency.

Picking

Working as a logistics operator requires very flexible systems to manage picking tasks. Whether working in a B2B or B2C environment is always a resource-intensive process.

It is essential to perform an analysis of the process itself and choose the most appropriate picking strategies and then apply the most suitable technologies, which can often vary depending on the work environment and the goods to be handled. In any case, the integration of the information in the company’s corporate systems must be optimized.

Picking

Working as a logistics operator requires very flexible systems to manage picking tasks. Whether working in a B2B or B2C environment is always a resource-intensive process.

It is essential to perform an analysis of the process itself and choose the most appropriate picking strategies and then apply the most suitable technologies, which can often vary depending on the work environment and the goods to be handled. In any case, the information must be integrated into the company’s corporate systems.

Dimensions: Volume, weight...

In addition to the identification of goods, it is often essential to add other information that adds value to the identification itself, such as volume and weight.

For this purpose, there are multiple technologies that offer variables such as weight, dimensions and volumetrics from full pallets to small packages, in automated, semi-automated or manual operations.

Dimensions: Volume, weight...

In addition to the identification of goods, it is often essential to add other information that adds value to the identification itself, such as volume and weight. For this purpose, there are multiple technologies that offer variables such as weight, dimensions and volumetrics from full pallets to small packages, in automated, semi-automated or manual operations.

Replenishment

Although it is defined that the picking process is the one that can commit the most resources, picking usually requires a correct management of replenishment and for this it is vital to be able to execute the planned orders and integrate the information in the information systems in an agile (real time is recommended) and accurate way.

Depending on the environment, the goods and the costs, it is possible to apply one technology or another, but always integrated and as automated as possible.

Replenishment

Although it is defined that the picking process is the one that can commit the most resources, picking usually requires a correct management of replenishment and for this it is vital to be able to execute the planned orders and integrate the information in the information systems in an agile (real time is recommended) and accurate way. Depending on the environment, the goods and the costs, it is possible to apply one technology or another, but always integrated and as automated as possible.

Inventory

Corporate Warehouse Management systems or ERP are responsible for managing inventory and keeping it alive.

Whatever your corporate warehouse management system will eventually be, it will require complementary systems to help you convert the actual physical movements into data, which is why it is essential to have the integration of technology in your management and control systems.

Inventory

Corporate Warehouse Management systems or ERP are responsible for managing inventory and keeping it alive. Whatever your corporate warehouse management system will eventually be, it will require complementary systems to help you convert the actual physical movements into data, which is why it is essential to have the integration of technology in your management and control systems.

Readings in a sorter

Sorters or automatic sorting elements, among other applications, are also used in order picking environments.

This type of sorter system allows sorting products based on orders with greater precision, simplicity and operational accuracy.

Readings in a sorter

Sorters or automatic sorting elements, among other applications, are also used in order picking environments. This type of sorter system allows sorting products based on orders with greater precision, simplicity and operational accuracy.

Mobility processes

In Transport & Logistic, logically, the management of deliveries/collections is carried out in mobility environments, external to the company. Optimizing, planning, managing and executing these tasks is, thanks to available technologies, possible in a centralized way, both for B2B and B2C (last mile) environments.

It is essential to integrate the information generated in the execution of these processes in a centralized repository where all departments and/or entities can access the corresponding information.

Mobility processes

In transportation and logistics, logically, the management of deliveries/pickups is carried out in mobility environments, external to the company. Optimizing, planning, managing and executing these tasks is, thanks to available technologies, possible in a centralized way, both for B2B and B2C (last mile) environments.

It is essential to integrate the information generated in the execution of these processes in a centralized repository where all departments and/or entities can access the corresponding information.

Asset location and traceability systems

The investment made in the company’s assets is very high, and a solution is needed to position the critical assets, and at the same time integrate this information with the management and control systems.

Asset location and traceability systems

The investment made in the company’s assets is very high, and a solution is needed to position the critical assets, and at the same time integrate this information with the management and control systems.

May we help you?

- +34 91 430 47 82

- info@tech-id.com

Phone: +34 914 304 782

E-mail: info@tech-id.com

Address: Calle Caléndula 95, Building O Office 9

28109 Alcobendas (Madrid)

Phone: +34 6 17 46 02 27

E-mail: info@tech-id.com

Address: Calle Calatrava 23, Barcelona

Phone: +34 886 061 600

E-mail: info@tech-id.com

Address: Pol. Ind A Portela, Nave 9, Avda. Puxeiros 86 (Mos, 36416, Pontevedra)

Phone: +39 011 18 98 3679

E-mail: info@tech-id.com

Address: Via Migliarone, 21/A

10091 – Alpignano (TO)

Phone: +39 039 51 58 592

E-mail: info@tech-id.com

Address: Via Berlinguer, 18

20872 – Cornate d’Adda (MB)

Find the solution to automate and optimize your processes and integrate all your corporate information. Ask us and together we will analyze your case.

May we help you?

- +34 91 430 47 82

- info@tech-id.com

Teléfono: +34 914 304 782

E-mail: info@tech-id.com

Dirección: Calle Caléndula 95, Edificio O Oficina 9

28019 Alcobendas (Madrid)

Teléfono: +34 6 17 46 02 27

E-mail: info@tech-id.com

Dirección: Calle Calatrava 23, Barcelona

Teléfono: +34 886 061 600

E-mail: info@tech-id.com

Dirección: Pol. Ind A Portela, Nave 9, Avda. Puxeiros 86 (Mos, 36416, Pontevedra)

Teléfono: +39 011 18 98 3679

E-mail: info@tech-id.com

Dirección: Via Migliarone, 21/A

10091 – Alpignano (TO)

Teléfono: +39 039 51 58 592

E-mail: info@tech-id.com

Dirección: Via Berlinguer, 18

20872 – Cornate d’Adda (MB)

Find the solution to automate and optimize your processes and integrate all your corporate information. Ask us and together we will analyze your case.